Did you know that efficient logistics management could be the difference between success and waste in food sector operations?

With ever more complex and demanding processes, well structured management allows greater trackability, optimization of resources and compliance with health standards.

Furthermore, technologies such as automation, smart sensors and artificial intelligence are transforming how companies monitor, take decisions and innovate in their operations.

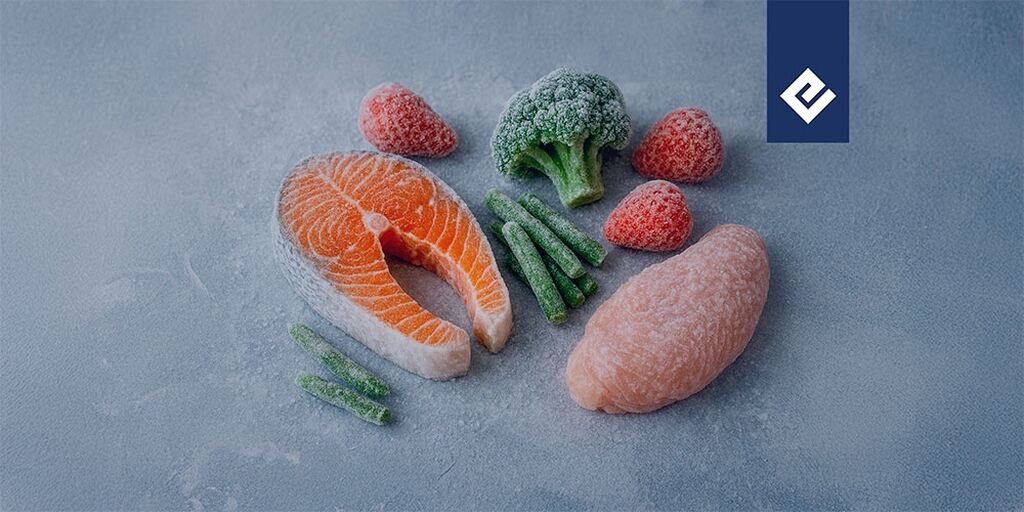

In the perishable foods sector, where time and temperature cannot be ignored, investing in logistics management is not just good practice — it has become an indispensable competitive strategy.

Find out more and how we can help!

What is logistics management?

Logistics management is the set of strategies and processes that guarantee the efficient flow of products, information and resources throughout the supply chain.

It goes from demand planning through to delivery to the end consumer, passing through stages such as storage, transport and distribution.

In the perishable foods sector, such as meats, fruits and dairy, this also includes care over the temperature, trackability and compliance with health standards.

Logistics management and its importance in the supply chain

Good logistics management brings concrete benefits: reduction of operational costs, greater predictability of delivery, reduction of waste and increased customer satisfaction.

In cold chains, well executed logistics avoids losses, guarantees the quality of the product and improves the competitivity of the company.

Types of logistics management

Below we go into greater detail about each stage in logistics management.

Stock management

Stock management involves the precise control of the entry and exit of products, guaranteeing that the company maintains the ideal level of goods to meet the demand.

In a cold chain, the stock of perishables needs to be monitored in real time to avoid losses through failures in the temperature or expiry date.

The use of integrated inventory systems and IoT sensors is one of the good practices that help improve accuracy and reduce waste.

Transport management

Transport management is responsible for the movement of goods between distribution centers and points of sale or consumption, and is indispensable in refrigerated chains.

Temperature-controlled trucks, combined with optimized routing, fleet maintenance, cost management, and integration with tracking systems, ensure that products such as meats and dairy arrive at their destination with quality fully preserved.

Furthermore, the efficiency in the deliveries contributes to the reduction of costs.

Warehousing management

This concerns the physical and logical organization of storage of the perishable products.

In cold chain environments, such as refrigerated rooms (normally between 0 °C and 5 °C) or frozen (at -18 °C or less), it is fundamental to maintain the temperature constant and to have an efficient layout that facilitates the movement of the items.

Warehousing management also includes the use of WMS systems (Warehouse Management System) that control the location of each product and optimize the picking and dispatch.

Distribution management

This refers to the delivery of the products to their destinations. In logistics of perishable foods, this means respecting the rigorous time periods and specific transport conditions. An error at this stage can compromise the whole load.

Efficient distribution management considers the type of product, volume, location of the client and health restrictions, guaranteeing a positive final experience.

What are the pillars of the logistics management business?

- strategic planning: anticipating demand and defining clear targets;

- integration of processes: connecting all the areas involved in the chain;

- technology and automation: enables trackability, agility and reduction of errors;

- monitoring of indicators: enables adjustments in real time and continuous improvement.

Best practices to optimize supply chain logistics

- use of WMS and TMS systems: enables greater control and visibility of the stock and transport;

- investment in modern infrastructure: refrigerated rooms, leveled docks and automated systems are fundamental for agility and safety;

- constant training of teams: well-trained staff are able to deal with critical situations and operate with greater precision;

- strategic partnerships: count on specialized logistics operators, such as Emergent Cold LatAm, guarantees compliance with standards and fulfillment of deliveries;

- monitoring of logistics KPIs: accompanying indicators such as cycle time, accuracy of the inventory and rate of deliveries on time helps decision making;

- flexibility and response capacity: adapting the operation in accordance with the seasonality or unforeseen market circumstances is essential to the continuity of service.

Be aware of the principal trends in logistics management

It is also important to emphasize that logistics is going through a real transformation, boosted by technological innovations, changes in demand from consumers and the need for greater sustainability.

In the field of automation, automated movement, separation and stocking systems have gained space, enabling gains in productivity, greater precision in the execution of tasks and less dependency on manual labor for repetitive activities.

Furthermore, smart sensors help monitor environmental conditions, especially relevant in the cold chain.

Artificial intelligence also stands out for its role in demand forecasting, optimization of routes and decision making in real time.

By integrating AI with logistics management systems, companies gain complete visibility of the operations and are able to act proactively when faced with problems, minimizing risks and maximizing efficiency.

Another point of attention is the search for more sustainable operations.

Reducing carbon emissions, using sources of renewable energy and optimizing exploration of energy resources in warehouses has taken place not only in competitive actions, but also in the demand from the market and international regulations.

These trends point towards a more connected, smart and responsible logistics, where the technology is not just a support, but the central axis of operational evolution.

Find out how our solutions boost innovation in cold chain logistics processes

Emergent Cold LatAm guarantees the safety and the quality of your products in the latest generation warehouses, with temperature-controlled and structure designed to attend to the highest industry standards.

Our solutions include:

- warehousing with temperature control — safety and integrity from receiving through to dispatch;

- refrigerated and efficient transport — we guarantee that your goods are moved at the correct temperature, tracked in real time, with rigorous control at each stage;

- value-added services — we offer picking, processing, packaging, labeling, among other services, adding efficiency and practicality to your operation.

Strategic network throughout Latin America

With a presence in 11 countries, our structure counts on:

- 82 warehouses strategically located in the principal urban and port centers;

- more than 500 vehicles prepared to attend to various demands, with agility and precision.

Technology and expertise in favor of your operation

We integrate leading edge technology with operational expertise to transform cold chain logistics.

With strategically located assets and modern infrastructure, we help our clients overcome logistics challenges, minimize losses and achieve greater efficiency in their operations.